Continuing the discussion from Removing the front cover plate on SC6000: This week i solve a major problem with the sc6000. The touch detection was working perfectly on the plater but the jog wheel doesn’t worked.

So i study the machine and carefully disassembled the thing. And found the problem. The jog wheel sensor wasn’t weld and barely touch the connector. Everything solve after i solder it.

So i take a moment to detail the disassembly.

Step1:

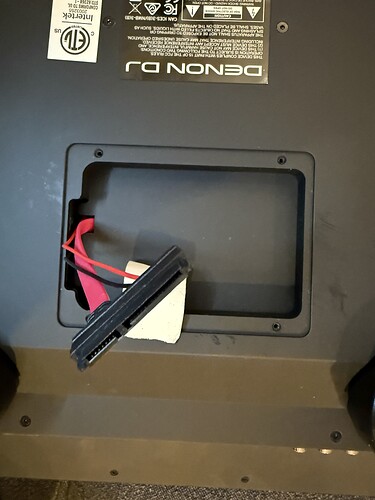

With a star screwdriver, remove the 4 screws from the hard drive plate.

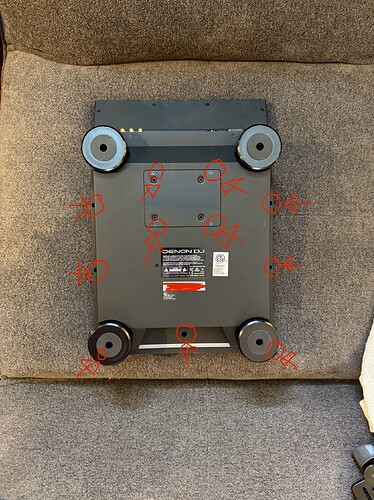

And remove 7 screws all around:

Step 2 Remove the tape in the hard disk area to free up the cable

Step 3

With a allen srew driver. Remove the 3 screws on the top of the Denon SC6000:

Step 4 Remove the 3 screws from the face of the Denon.

Step 5

Remove the srews from the bottom. Caution to the length of them they are different from the top and face.

Step 6

Remove 2 screws each side of the sticker. They are metric screws. Remember.

Step 7

By the table feets, trow the cover. It will slide a bit to the front to clear the usb and card connections.

Pass the hard disk cable in the hole. Voila the machine are open

You want some more?

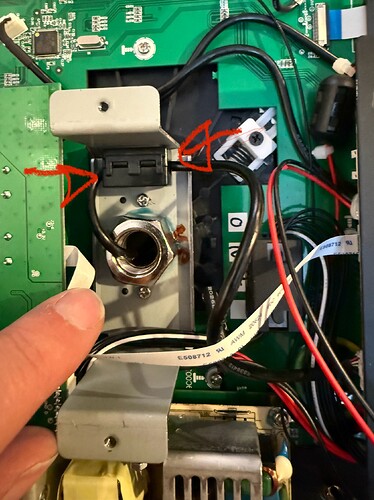

Here the way to disassemble the plater. Under the motherboard. Disconnect the cable with a small screw driver.

Now, unclip the black square thing to free up the black cable.

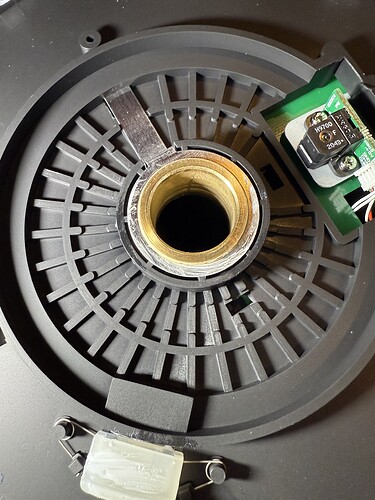

With a key, remove the big nut. It stick with locktite so need a bit of force.

Note i make a mark to identity the up and down. Very important if you don’t want a reverse screen😉.

Remove the 2 screws and carefully remove the metal plate. Be careful with the cable around.

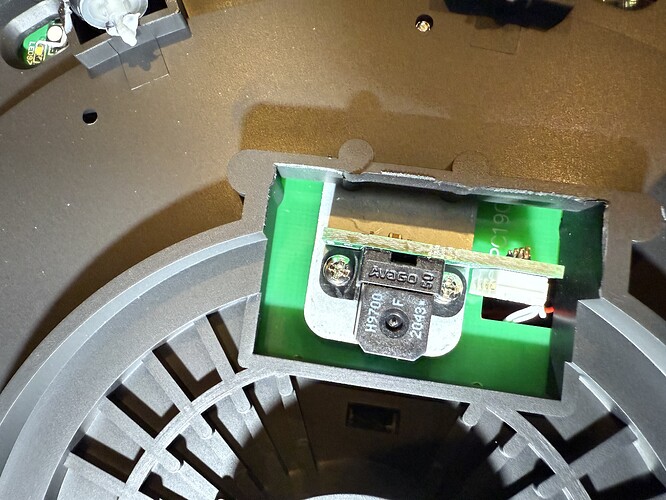

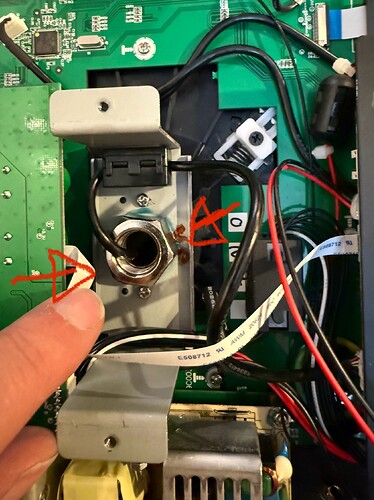

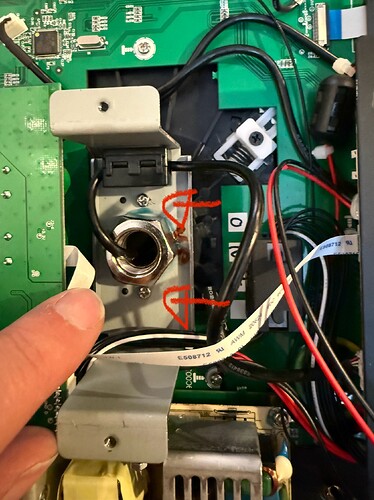

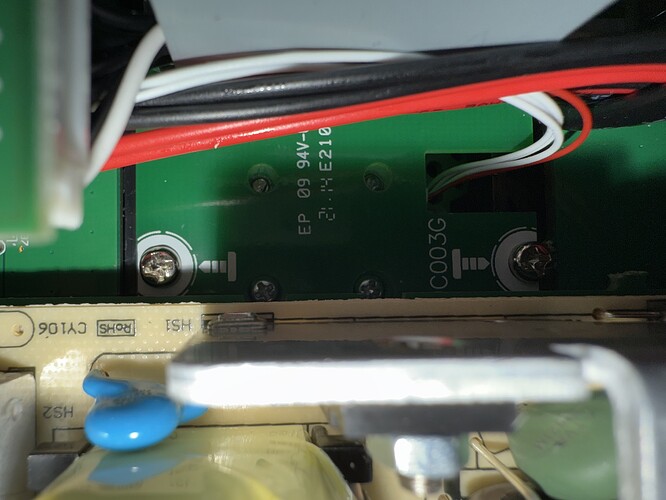

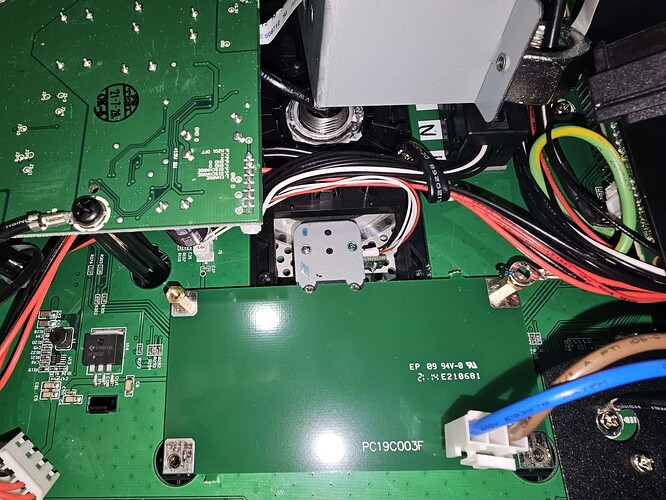

After you remove the metal plate, on the left side of the table( you right because the table are flip) you will see a green board without electronics. Just bellow the yellow board Here:

Remove the two screws

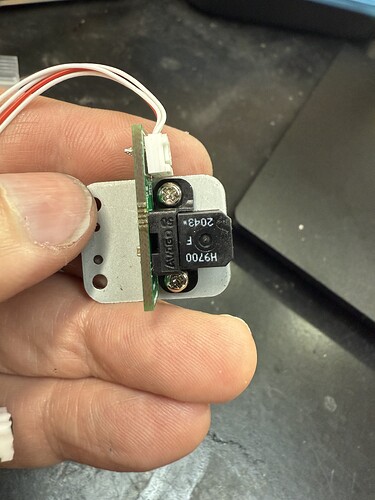

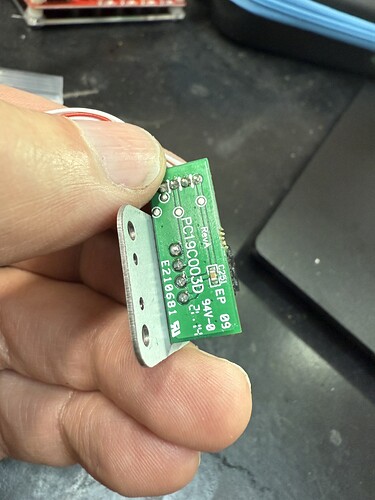

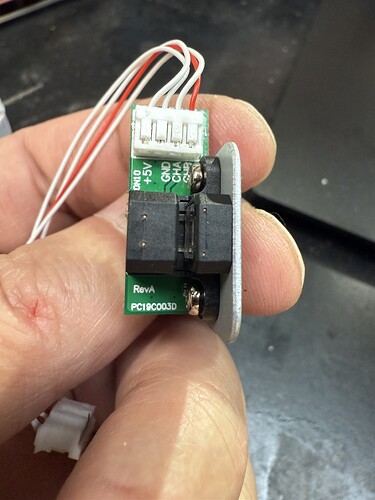

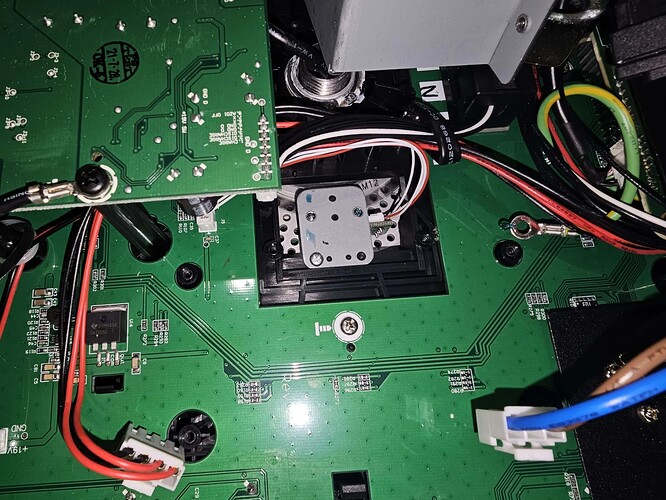

Under this you have the metal plate holder for the jog wheel sensor. Remove the 2 screws and carefully remove the sensor without damaging the sensor disc. Sorry i forgot to take a picture but i give you one from the other side to understand .you will free up the sensor. Disconnect it from the board

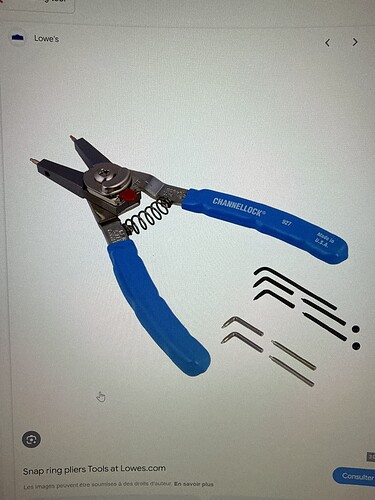

Ok now the serious thing🤣. On the big shaft where you remove the nut. You will find a locker ring. You need a tool to remove this kind of ring . it’s a ring pliers.

After you remover the ring, the plater are free to remove. Take care of the sensor disc

Clean everything as new. I clean the shaft, the bushings , and the break with isopropyl alcohol.careful with the disc.

I use lithium grease on the shaft, the bushing and the brake. Also on the pivot on each wheel.

Check the weld on the sensor. It was my problem ![]()

Now reassemble. Congrat, your table will work better than ever. The plater are smoot like a real one. The brake come back like new. No more rubbing sounds or loose plater. The original grease was a ■■■■!

Cheers